- HOME

- >

- Company Information

- >

- Company Profile

Company Profile

Company Profile

| Company Name | MEIHO CO., LTD |

|---|---|

| Officer | Representative President: Katsuhiko Nagamatsu (Mr.) Executive Managing Director: Seiji Katsuki (Mr.) Executive Director: Yuji Takashima (Mr.) Auditor: Yoshihiko Nakao (Mr.) |

| Founded on | January 18, 1973 |

| Capital | 100 million yen (JP100,000,000yen) |

| No of Employees | 180 employees |

| Head Office | Business Management Div. / Sales Development Div. 811-1, Ganda, Nogata, Fukuoka, 822-0001, Japan TEL:+81-949-26-0006 (Pilot) FAX:+81-949-26-3800 |

| Tokyo Office | Market Development / Sales #103, 4-35-21 Tsurumichuo,Tsurumi, Yokohama, Kanagawa, 230-0051,Japan TEL:+81-080-4047-1443 |

| Factory | MEIHO Second Factory / Mold Die Production Div. 811-1, Ganda, Nogata, Fukuoka, 822-0001, Japan TEL:+81-949-26-0006 (Pilot) FAX:+81-949-26-3800 MEIHO Third Factory/ Molded Item Production Div. / R&D Center 287, Ton'no, Nogata, Fukuoka, 822-0002, Japan TEL:+81-949-26-5020 (Pilot) FAX:+81-949-26-6933 |

| Main Buyers and Suppliers | Semiconductor Makers, Electronic Parts Makers, Car Parts Makers, Molding Machine Makers, Medical Device Makers, Chemical Makers, Container Makers, Robot Makers, etc. |

| Banks | THE NISHINIPPON CITY BANK, LTD. The Shoko Chukin Bank, Ltd. THE KITAKYUSHU BANK, Ltd. |

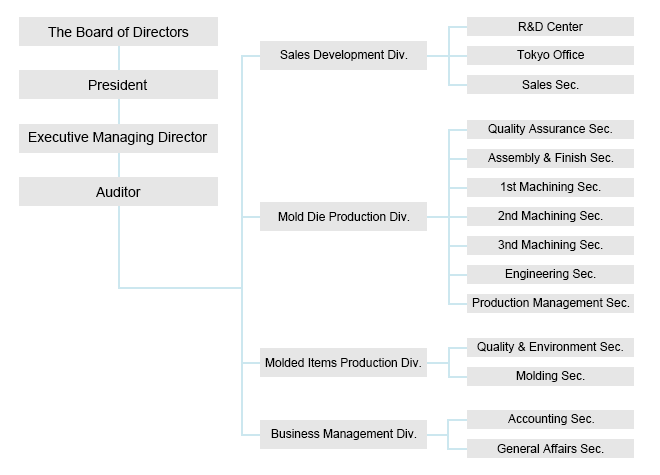

Company Organization

Lift of Offices and Factories

Head Office, MEIHO 2nd Factory: Mold Die Production Div.

811-1, Ganda, Nogata, Fukuoka, 822-0001, Japan TEL:+81-949-26-0006 (Pilot) FAX:+81-949-26-3800

MEIHO's 3rd Factory / R&D Center

287, Ton'no, Nogata, Fukuoka, 822-0002, Japan TEL:+81-949-26-5020 (Pilot) FAX:+81-949-26-6933

Molded Items Production Div.

Assembling of Electronic Parts, Production of Plastic Injection-molded items, LED parts, Liquid Silicone Rubber Molded Items (LIM Molded items), and Complex-Molded items.

R&DCenter

Research and Development of MEIHO's new products, unique technology, labor-saving machines.

Tokyo Office

#103, 4-35-21 Tsurumichuo,Tsurumi, Yokohama, Kanagawa, 230-0051, Japan TEL:+81-080-4047-1443

Marketing and Sales of Mold Dies and Molded items

Company History

| Jan.1973 | Started to design & manufacture Precision Mold Dies for injection molding. Decided its business name as MEIHO SEIKO (Precision Engineering) |

|---|---|

| Jan.1977 | Changed into Corporate Organization. Also Changed its business name into MEIHO CO.,LTD. The capital was 5 million yen (5,000,0000yen) |

| Aug.1978 | Started to design & manufacture Biaxial Stretching Blow Mold Dies. |

| Apr.1979 | Started to design & manufacture Lead-Frame Mold Dies for Semiconductors. |

| Feb.1981 | Started to design & manufacture Precision Mold Dies for Semiconductors. |

| Oct.1981 | Started Injection Molding Processing for Precision Resin Parts. |

| Aug.1991 | Started to design & manufacture Precision Press Mold Dies. |

| Jul.1998 | Developed thermoplastic-resin-using Semiconductor Sealing Machines and Ultra Compact Injection Molding Machines. |

| Aug.1999 | MEIHO's 3rd Factory (in Nogata) obtained Quality Management System ISO9001 Certification. |

| Nov.2002 | Started to manufacture Precision Insertion Molded items for Cars. |

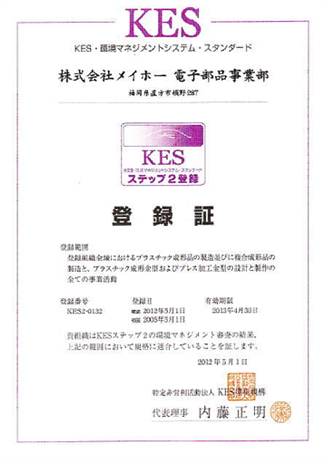

| May.2005 | MEIHO's 3rd Factory (in Nogata) obtained Environment Management System KES・Step2 Certification. |

| Oct.2007 | Started the integrated production of connectors for electronic devices by using our own developed Ultra-Compact Injection Molding Machines. |

| Jan.2008 | Assisted by advisory experts on the advancement into car industry, and then started to learn TPS Theory and carry out the TPS-based improvement |

| Apr.2010 | Started the integrated production of LED parts by using our own developed Ultra-Compact Injection Molding Machines. Started the integrated production of Liquid Silicone Rubber (LSR). |

| Aug.2012 | Started the integrated production of Bio-Vessels for Medical Use by using our own developed Ultra-Compact Injection Molding Machines. |

MEIHO's Equipment & Facilities

Molding Machines / Press Machines

| Facility Name | Maker | Model Type | No. |

|---|---|---|---|

| Injection Molding Machines | NISSEI PLASTIC INDUSTRIAL Sodic Plustech MEIHO-made |

1t~200t NEX30~50 TR40EH2 UH1000-60 Micro-2,2H(MEIHO-made), etc. |

50 |

| LIM Molding Machines | NISSEI PLASTIC INDUSTRIAL | TNX100R5VLM TNX75R5VLM, etc. |

5 |

| Press Machine | JAM Towa Seiki Aida Engineering KOEI |

HYP505 TEP235 BSTA25V KPH-10M, etc. |

11 |

Designing Software

| Facility Name | Maker | Model Type |

|---|---|---|

| CAD | SolidWorks C&G Design Creation Toyota Caelum Fujitsu |

SolidWorks CG Mold Design CG Press Design EXCESS-HYBRID CADPAC CREATOR ThinkDesign SolidMX |

| CAM | C&G Toyota Caelum ISID MAKINO |

CG CAM-TOOL Caelum KKen NX FF-CAM |

| CAE | Autodesk SolidWorks |

Autodesk Simulation Moldflow SolidWorks Simulation Professional |

Mold Die Machining Machines

| Facility Name | Maker | Model Type | No. |

|---|---|---|---|

| Machining Center | Yasuda,Makino | 640V,V33,V56i,etc | 17 |

| Electric Discharge Machining Devices | Makino,Sodic | EDAF3,EDGE3,etc | 10 |

| Wire Electric Discharge Machining Devices | Makino,Mitsubishi | W32FB,W53FB,etc | 6 |

| Surface Grinding Machines | Nagase,Mitsui High-Tech | SGC840α,etc | 20 |

| NC Milling Machine | Makino,Shizuoka,Okuma | AN-SRN20,etc | 9 |

| NC Lathe | DMG Mori Seiki,Okuma | NL2500Y,NLX2500,etc | 7 |

| Gun Drill | Hi-tac,Miroku | TGS-1000SC-TSS,etc | 2 |

| Jig-Tool Grinding Machines | Mitsui Seiki | 3GB | 2 |

Inspecting Devices

| Facility Name | Maker | Model Type | No. |

|---|---|---|---|

| CNC Image Measuring Machine | NIKON | NEXIV VMR3020 | 1 |

| 3D Measuring Machine | Mitutoyo | BH303 | 1 |

| All-Purpose Tool Microscope | TOPCON,Mitutoyo,NIKON | TUM220EHn,TUM220EH,TUM200BD,TUM130D, MF series,MM series |

5 |

| All-Purpose Projector | NIKON | V-24 | 2 |

| Surface Condition Measuring Device | Mitutoyo | SV-C3100 (Surface Test・Contracer) |

1 |

| Length Measuring Device | HEIDENHAIN | METRO MT60K,MT101K | 14 |

| Digital Height Gauge | TESA | Plus M600 | 1 |

| Noncontact Depth Measuring Device | UNION OPTICAL | DH-2 HisometⅡ | 3 |

| Ultrasonic Thickness Gauge | KRAUT KRAMER | 1 | |

| Noncontact 3D Measuring Device | MITAKA KOHKI | NH120S | 1 |

| X-Ray Inspection Device | SHIMADZU | TREX610 | 1 |

| Microscope | KEYENCE | VHX・VH-Z75 | 2 |

MEIHO's Green(Environmental Protection) Activities

MEIHO's Green Slogan

MEIHO shall fully satisfy its Social Responsibility for Bright & Rich Future of our Earth.

MEIHO's Principles on Environmental Protection

MEIHO fully recognizes the global environmental protection as one of the most important challenges for all the human beings on earth. So the whole organization of MEIHO shall try our best and make all possible efforts to reduce environmental load for the future of our earth.

MEIHO's Policy on Environmental Protection

MEIHO always aims to actively promote its own Environmental Management Actions based on the following policy and carry out all the necessary activities for environmental protection to harmonize its business activities with the global green environment. The policy below is designed for reducing environmental load which may come with all our business activities, products and services.

- MEIHO shall always recognize the environmental load which may come with its business activities, products and services, actively promote the prevention of environmental pollution and be devoted to the continuous improvement in its own Environmental Management Actions.

- MEIHO shall follow, observe and respect all the laws, regulations, requirements and obligations associated with its business activities, products and services.

- Among all the environmental affecting matters which may come with its business activities, products and services, MEIHO shall recognize the following items as Special Environment Management Items, and control and manage all the affairs associated with these items.

- MEIHO shall assure that each of its employees are well-informed and known of this MEIHO's Policy on Environmental Protection so that each of the employees is able to actively carry out necessary activities reducing environmental load. MEIHO shall also announce this MEIHO's Policy on Environmental Protection to companies and people outside.

In order to achieve the above Policy Environmental Protection, MEIHO shall set goals to achieve this Policy and, on the regular basis, MEIHO shall revise the Policy. Then, MEIHO actively promotes its Environmental Protection Management System

MEIHO's Environmental Commitment

MEIHO (Its Third Factory) CO., LTD. fully recognizes the global environmental protection as one of the most important challenges to achieve, and so sets the following as our Green Slogan: "MEIHO shall actively promote Environmentally Friendly Business Management for the tomorrow of our bright, green and rich earth." With this slogan in mind, MEIHO has been actively promoting its Environmentally-Conscious Business Management in its all business activities. Our environmental protection activities include, but not limited to, 1) Development of Eco-Friendly Products, 2) Energy-Saving Commitment, 3) Reduction in wastes, 4) Recycling of Wastes, and many other things. In the year of 2005, we successfully obtained "Environment Management System KES Step 2" Certification. Also we have been devoted to continuously review and improve our Environmental Protection Activities for more successful results we can surely get. MEIHO always aims to be able to make a lot of contributions to its local communities, country and our earth, in the field of environmental protection, by actively carrying its green activities designed for reducing environmental load.

Collection of Classified Refuse・Recycle: Wasted Plastics, Refuse of Pressed Materials, Refuse of Composite Molded Items, Metals, Paper, Cardboard Papers

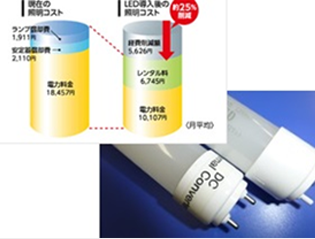

Reduction in Power Consumption by Replacing Lights with LEDs

"Green Activity Promotion Section" has been set up in our Office and Factories.

Mold Die Production Div.

Designing and Manufacture of the following items:

・Precision Mold Dies for Semiconductors, Blow Mold Dies, Precision Mold Dies for Injection Molding,

・Liquid Silicone Rubber Molding Dies (LIM Mold Dies), and Precision Machine Parts